Home - Products - Decorative Line - Stables Line Paints - Lignum Impregnante

Code: 6D & 6EL

High quality product that combines the quality of an excellent wood sealer with the feature of a good finishing topcoat. The high penetration power, its fungicides, anti-woodworm and anti-mildew characteristics make it the ideal product for wood protection. The colourless version enhances the wood natural woodgraining, while the standard colors allow to give to the wood the same shade of light wood like pine or fir. The special transparent pigments used in its formulation, in addition to an exceptional light and weather resistance, enhance the natural woodgraining of wood. Lignum impregnante it is used not only as a conventional sealing coat for standard wood coating system overcoated with a transparent varnish or a coloured enamel, but it can also be used as a finish coat itself performing a nice finish easy to maintain and renew. The first coat sinks completely into the wood substrate ensuring a deep protection. The product allows an easy sandpapering of the surface, necessary to obtain a soft and velvet like finish. The application of at least another 2 coats are generally required to provide a good protection and finishing without too much thickness, which would otherwise make the renewing operations more difficult. The natural finish can be renewed in the long run simply with a single coat of product each time a maintenance coating is required. The application of LIGNUM IMPREGNANTE saves expensive maintenance costs and keeps the wood at its best. Its easy application is a guarantee of good results. (Formulated with Bayer raw materials).

SURFACE PREPARATION AND RECOMMENDED COATING SYSTEM

Bare wood. The wood surface should be preferably dry, seasoned and clean. Apply the first coat of LIGNUM IMPREGNANTE in order to sink deeply the pores of the wood . After 24 hours you can apply further 2 coats of LIGNUM IMPREGNANTE to get a natural semi-gloss finishing. It can be overcoated with 2 coats of LIGNUM CERATO.

Note: In case LIGNUM IMPREGNANTE is overcoated with synthetic varnishes (such as TOPKAPI UV, BEKOL, SUPERWIND or STARWIND UV etc.) or in some cases with one-component enamels (such as SINTOLIN or TOPKAPI) it is recommended that a waiting time of 3-4 days should be elapsed after the application of LIGNUM IMPREGNANTE to allow the product to fully dry.

| Paint Type | One component |

| Binder type A | Urethane modified |

| Specific gravity kg/lt (±0,05) | 0.870 |

| Solids content (weight) ±2 | 31% |

| Shelf life +23°C (±2) | 36 months in unopened cans |

| Note | Store in a cool, dry place. Do not store at low temperatures. |

| Viscosity Ford (Ø4 a 20°C) | 12±2 sec. |

| Application | Brush-Roller |

| Brush-Roller | Ready for use or if required 5% Thinner 107 |

| Touch dry | 1-2 h |

| Recoat time | Between 2 coats of Lignum;24 hours - if overcoated with a varnish wait 3-4 days (20°C) |

| Relevant humidity | Less than 80% |

| Theoret. coverage m2/Lt | 10-12 depending on wood absorption |

Colors: Incolore

Color code: 6D0000

Colors: LIGNUM LARICE

Color code: 6EL101

Colors: LIGNUM LEBANO

Color code: 6EL106

Colors: LIGNUM NOCE CHIARO

Color code: 6EL103

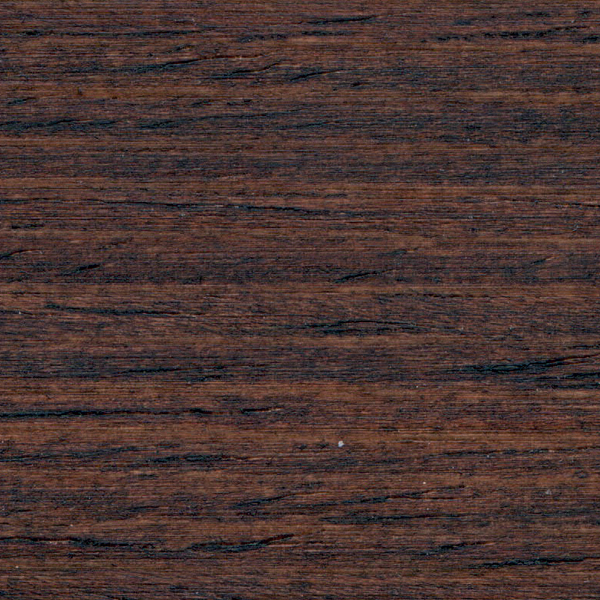

Colors: LIGNUM NOCE SCURO

Color code: 6EL104

Colors: LIGNUM PALISSANDRO

Color code: 6EL105

Colors: LIGNUM TEAK

Color code: 6EL102

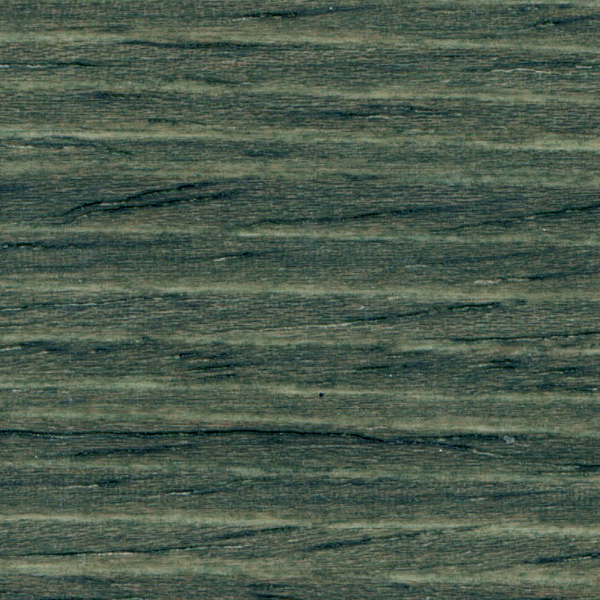

Colors: LIGNUM VERDE

Color code: 6EL107

SAFETY PRECAUTIONS

Before starting paint application please carefully read all the safety precautions indicated on the label of each can or in the product safety data sheet available on request. For further information please do not hesitate to contact our technical staff.

NOTES

The above information is given to the best of our current knowledge, however, because the conditions of use of our products are beyond our control, no warranty is given or to be implied in respect of such information. Our technical staff can be contacted to study customer's specific requirements involving our products in order to enable their most effective use. Dilution rates and drying times must be considered only indicative, mainly related to a temperature of 20 ° C (68°F) and may vary according to prevailing temperature, in presence of particular weather conditions or depending on application procedures.